Al-foil thawv composite ib zaug dhau formong pwm

Muaj nuj nqi

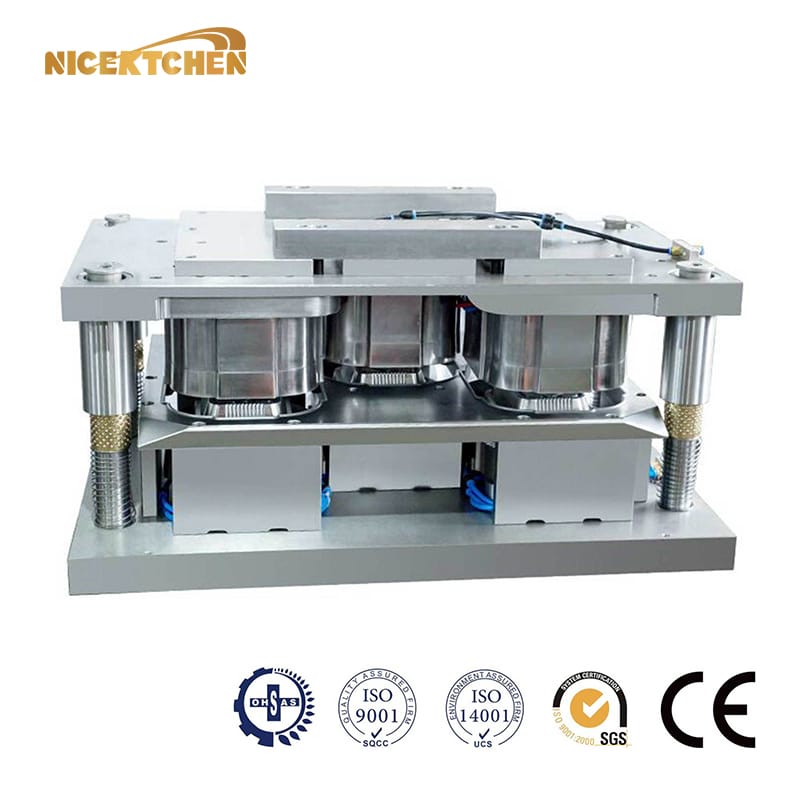

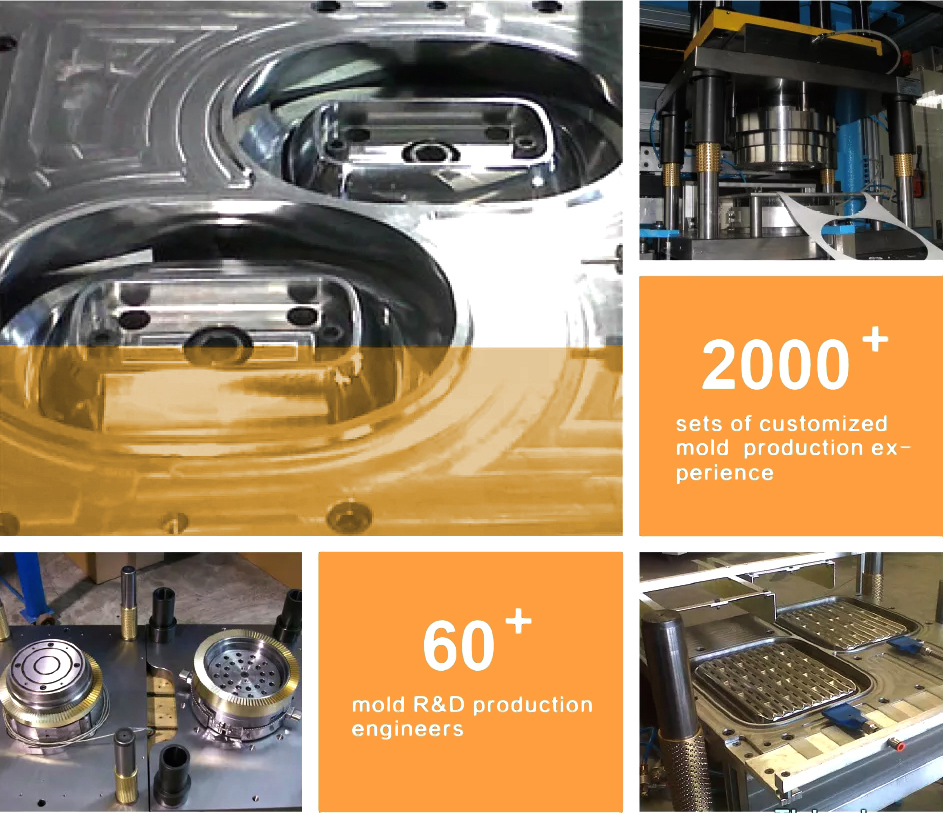

Peb lub tuam txhab pib ntawm lnternational thiab lub teb chaws monld's feature, los tsim thiab manufocture tshiab hom composite ib leeg-pass formong pwm.

Khoom nta

1 、 Txais cov khoom siv los yog lub teb chaws alloy steel kom paub tseeb tias pwm khiav hauv kev kub ceev.

2, Pwm tus qauv tsim kom zoo, huab cua channel tsim kom zoo, kuj muaj lubrication system.

3 、 Txais siab zaus los yog sib kis ntawm cov pa roj carbon monoxide ua haujlwm siab, kom ntev pwm lub neej ua haujlwm.

4 、 Txais kev ua haujlwm tshwj xeeb los tsim pwm hauv cov duab sib txawv.

Cov ntaub ntawv technical thaum kho pwm

| Cpacity | Dimension ntawm lub rooj ua haujlwm | Dimension ntawm slider hauv qab | Dimension ntawm tuag shank |

| Stroke ntawm slider | caj pas tob | Kaw qhov siab | Kev kho qhov siab kaw |

Tuag Description:

◆ Raws li cov yam ntxwv hauv tsev thiab txawv teb chaws, peb lub tuam txhab ntawm nws tus kheej tsim thiab tsim cov kev sib txuas tshiab kawg nkaus ib zaug dhau los ua tuag, uas muaj cov yam ntxwv hauv qab no:

◆ Domestic los yog imported alloy steel yog siv los xyuas kom meej kev kub ceev ntawm cov tuag.

◆ Muaj kev tshaj lij cua Circuit Court tsim thiab lubrication system.

◆ Cov pa roj carbon ntau lossis cov tshuab ua haujlwm ntau zaus tau txais los ua kom ntev lub neej kev pabcuam ntawm cov neeg tuag.

◆ Peb siv cov txheej txheem tshwj xeeb ds los ua ntau hom pwm.

◆ Die forming txoj cai Lub sab saum toj tuag txav mus rau tus txiv neej txiav tuag, txiav tus poj niam tuag, thiab lub Upper tuag tswj

◆ Thaum txav mus los, lub qhov khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob.

◆ Thawj theem kev kos duab tuag txuas ntxiv mus, thiab theem thib ob kos duab tuag paub txog theem ob ntawm kev kos duab, thiab tib lub sijhawm, cov ntawv cim khoom raug thawb tawm.

◆ Punch siab tshaj qhov chaw tuag hauv qab.Lub nplhaib tuav lub nplhaib thiab thawj theem poj niam tuag tsim lub nplhaib dov qhov chaw nyob rau hauv qhov kev txiav txim ntawm lub tog raj kheej qis kom yob cov khoom rau hauv lub voj voog thiab txuas ntxiv mus.Lub tog raj kheej qis ejects cov khoom thiab tshuab tawm cov pwm nyob rau hauv qhov kev txiav txim ntawm lub blower.

Peb lub tuam txhab raws li lub teb chaws los yog txawv teb chaws lub feature, tshawb fawb thiab tsim peb tus kheej, thiab tsim lub xeem tshaj composite sing-pass forming tuag, muaj cov nram qab no nta:

Peb txais yuav cov hlau los yog cov hlau txawv teb chaws, xyuas kom pwm tuaj yeem khiav hauv kev kub ceev.

Pwm thav duab hauv kev tsim, cua channel tsim tshwj xeeb, thiab nrog lubricating system hauv.

Peb txais yuav siab zaus los yog kis tau ntawm cov pa roj carbon siab ua haujlwm ua haujlwm, kom ntev pwm ua haujlwm lub neej.

Peb txais yuav cov txheej txheem tshwj xeeb los ua cov pwm ntau yam.

Txoj cai ntawm molding

puab pwm txav mus rau txiav txiv neej tuag, thiab txiav poj niam tuag txiav cov khoom, sab sauv pwm cia

txav mus los, tus neeg tuav pov hwm thiab txiav cov txiv neej tuag ua rau lub cev tsis muaj zog nyob rau hauv qhov kev txiav txim ntawm hauv qab lub tog raj kheej, thiab paub txog thawj theem stretching nyob rau hauv qhov kev txiav txim ntawm lub puab puab core thiab hauv qab pwm core.

Thawj theem stretching poj niam tuag txuas ntxiv mus, kom paub txog qib thib ob stretching nrog qib thib ob stretching txiv neej tuag, ejector ua rau kos npe rau cov khoom tib lub sijhawm.

Punch siab dhau qhov kev tuag hauv qab no.Cov neeg tuav khoob thiab thawj theem poj niam tuag los ua ib qho chaw yob nyob rau hauv qhov kev txiav txim ntawm hauv qab lub tog raj kheej, dov cov khoom rau hauv ib puag ncig thiab txuas ntxiv mus, cov hauv qab lub tog raj kheej tshem tawm cov khoom tawm, thiab tshuab tawm ntawm cov pwm hauv qhov kev txiav txim ntawm lub tshuab.